Beahm 410-A Horizontal Laminator

Beahm 410-A Horizontal Laminator

Couldn't load pickup availability

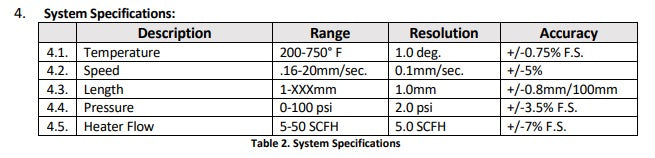

The Horizontal Laminator, a semi-automated device, is expertly designed for the lamination of plastic over braided catheter shafts. It features a sealed linear actuator that moves a multi-port thermal nozzle across a predetermined distance to achieve precise lamination. With its motion control system equipped with a keypad for parameter input and an individual temperature controller, users can accurately set the length, speed, and temperature for optimal lamination results. This device caters to a broad spectrum of requirements through its versatile configurations and options.

Key Advantages of the Horizontal Laminator:

- Precision in temperature regulation and targeted air flow, with a temperature capability ranging from 200-750°F.

- Exact control over traverse speed and length, alongside straightforward adjustments for parameters.

- A standard traverse length of 18 inches, with additional options for lengths of 36 inches, 60 inches, or 96 inches.

- Flexibility in orientation, allowing for either horizontal or vertical setups.

- Highly customizable in terms of product clamping and nesting features.

- Option for CE compliant guarding for enhanced safety.

This system is tailored to accommodate the most rigorous lamination demands, offering precise control and adaptable configurations for superior catheter production

(Missing Nozzle)

Share